WE MADE IT – we did it! What started as a daily driver project, transformed into a serious restoration and finished as our wedding chariot. My fiancee and i tied the knot on Sunday, May 27th with a wedding nothing short of amazing. And getting this car completed on time was definitely a part of that weekend. 4 days and 10 people later, the 280z barreled it’s way over to our hotel and drove us to our wedding.

Truly starting the week before, I had already ordered the parts i had needed for the final assembly – window seals, weatherstripping, carpet, seat covers, and a front windshield (more on that later). I needed to those parts ordered quick to be ready as soon as the car came back. Once the car rolled out of the painters garage it was already Tuesday evening – literally only 4 days and 5 nights remaining. That night i got straight to it, sorting out the pieces getting it ready for a full attack the next day. We quickly got into full swing with my brother Kris and a groomsman Erik helping hammer it’s way back to road-worthiness.

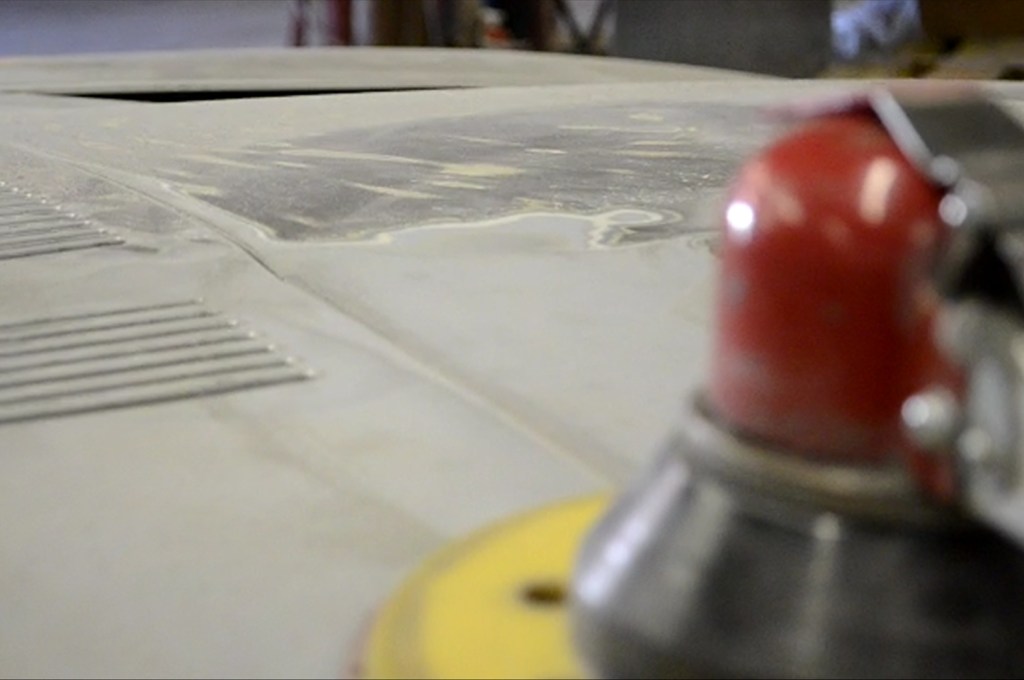

We were able to complete the rear tail lights, some trim repaint, side marker lights, headlights, hood louvers, hood rubbers, floorboard prepping, and the front feet area of the carpet.

Thursday rolls around for another big day. During the afternoon I had the neighbors install the front and rear windows – truly a blessing to have a family who owns an auto glass repair company live next door to you! Late afternoon, brother brought over another groomsman Jerry and his girl Kennie (who had just both come over from Hong Kong) to lend a hand, helping clean windows and tackle the carpet. Carpet continued to dominate our time because of the measuring / cutting required for all the interior fittings: both sides of the seat belts, shifter, e-brake, and seat rail holes among other things. Carpet needs to go in first because it instantly transforms the visual impact of the car. Additionally, once that’s in, seats, center console, door trim, all that can go back in.

Later that evening, I had three more sets of hands arrive: my future sister-in-law Dana, my sister Kathryn and her boyfriend Jake! It was great, we all had our hands on this thing! Jake and Jerry tackled doors, Kennie and Dana helped clean parts, Kathryn helped me assemble the last seat, while Kris had the dreadful task of installing the rear driver-side interior quarter panel trim. Imagine having so many people who, for the majority, have never worked on cars (let alone re-assemble one) all help out at the same time – yes, it was a circus. Yes, you’ve gotta make sure all the correct bolts were used. But truly it was such a fun experience. I love working on projects with friends, more so with my brother and sister!

To top off the night, even LATER that evening, my parents flew into town, and they too dropped by to check out how things were going. I wish i got it on video / photo, but both my mom and dad would later return the next day to help out to complete the re-assemble.

Friday, My dad and i put in the seats, dash and door trims; while my mom cleaned parts, and even tackled the biggest task: clean / organized the storm of parts and trash that my garage was left in the previous night. Yes, I definitely should have gotten photos of my mom and dad helping out but we were just so focused on getting this done. Wipers went on, the last three pieces of chrome front windshield trim were found and installed. I got to say the whole project has been amazing, but there’s nothing like working on a car with your dad. More over, he’ll be driving it while we’re away on our honeymoon. It’ll be 40 years since he last drove a Z, and I can’t wait to hear what he’s got to say!

I had a two hour window to install the final touches late Saturday afternoon – front grill, front parking lights and their trim, horn, side-view mirrors, and of course, the c-pillar ‘Z’ markers. I took it off the battery tender attached the night before, and started him up. Perfect – solid and strong. Looks – amazing and fast. I’m proud and thankful that my friends and family helped get car back on the road, and ready in time for the wedding.

Sunday night we drove it back from the reception only to be stopped by a police officer 1/4 mile from our hotel. Doh. Were parts falling off? Lack of rear bumper? Nope. No tail lights. Brake lights were working but the car was “invisible out there” with no running tail lights. Luckily the officer was more concerned about our safety, and with the ‘Just Married’ sign and us still being in our wedding get-up we were let go with a congrats rather than a ticket. :] Sigh! now this rebuild story is complete!

Pictures of the re-assemble will come soon – for now here are some pics straight from the painter that Tuesday afternoon.